Networked Labs-on-Chip

Labs-on-Chips (LoCs) allow for the miniaturization, integration, and automation of medical and biochemical procedures. To this end, LoCs combine different laboratory functions on a single chip, which yields a faster analysis as well as larger throughput while, at the same time, requires a significantly lower reagent consumption. LoCs are successfully used e.g. for in-vitro diagnostics, DNA sequencing, cell analysis, protein crystallization, or drug discovery.

A Biocompatible LoC Technology: Concepts of NLoCs

In Networked Labs-on-Chips (NLoCs), tiny volumes of fluids, so-called droplets, flow inside channels of micrometer-size (triggered by pressure). The closed channels allow for an incubation and storage of liquid assays over a long period of time and, by this, avoid evaporation and unwanted reactions. Recently, additional networking functionalities have been proposed, which enable the designer to dynamically select the operations to be conducted. These networking functionalities exploit hydrodynamic forces acting on droplets, and hence, increase the flexibility, effectiveness, as well as re-usability of NLoCs. Besides that, NLoC devices can be produced at low cost (e.g. using 3D printers) and are easy to use.

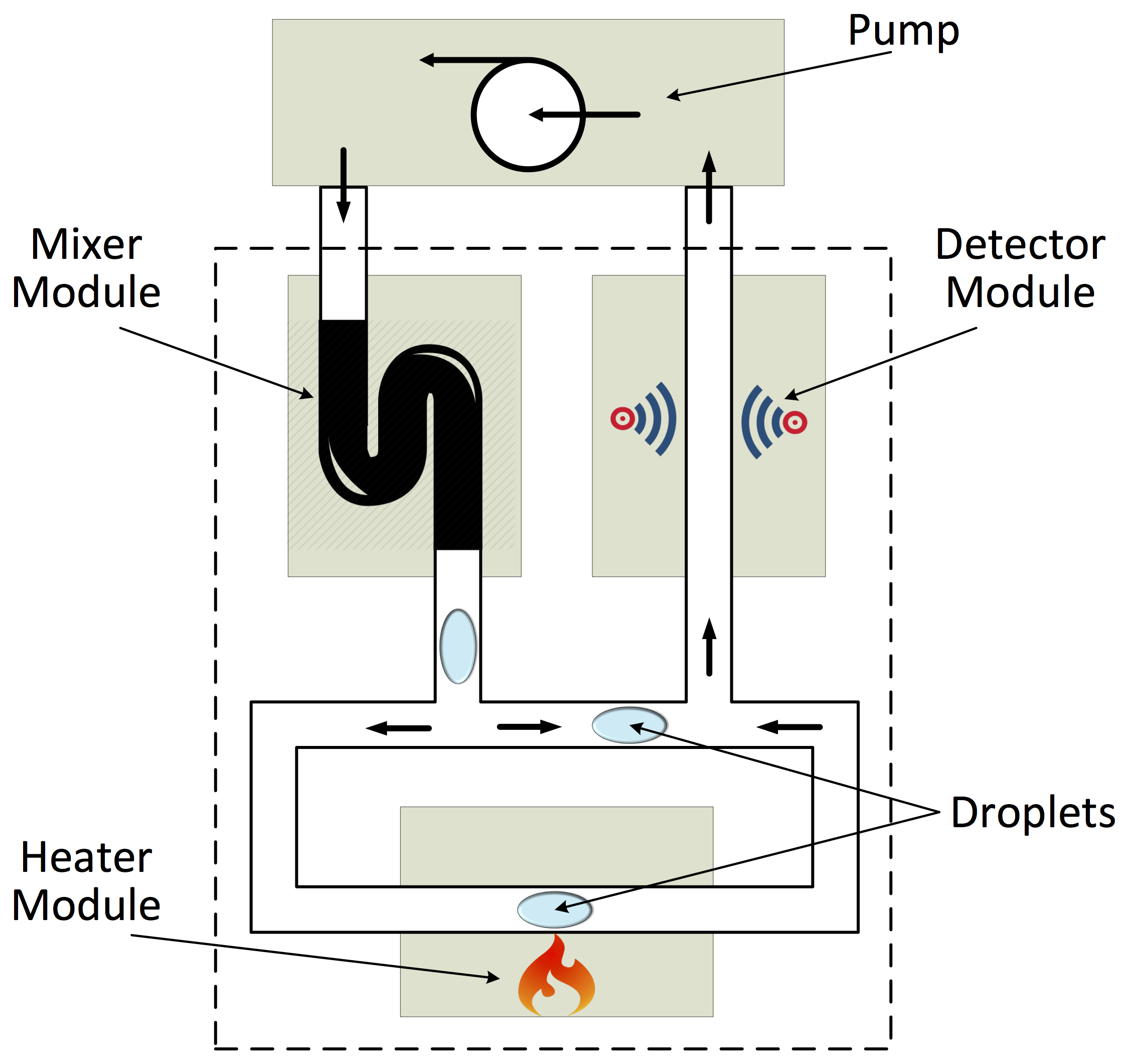

Experiments are conducted by executing operations on the droplets. These operations are implemented by modules, which are arranged along multiple paths through the NLoC. These paths are built by bifurcations of channels, i.e. the splitting of a channel in two or more successor channels. The figure on the right-hand side shows a schematic of an NLoC, which enables the designer to decide whether droplets should be heated or not before they get analyzed by the detector module.

Exploiting Hydraulic Resistances: Routing of Droplets in NLoCs

When a droplet arrives at a bifurcation, it will flow along the successor channel with the lowest hydraulic resistance (defined by the channel’s geometry). By that, the droplet itself increases the channel’s hydraulic resistance and, therefore, temporarily “blocks” this channel for following droplets. This principle of selectively blocking channels is eventually used to route droplets through the NLoC.

The following two videos show a physical realization of a bifurcation. The left video shows droplets flowing along the “default channel” (technically, the channel with the lower hydraulic resistance). In the right video, the second droplet is intentionally routed to the successor channel with the initially higher hydraulic resistance. This is possible as the first droplet the hydraulic resistance of the default channel, so that the following droplet takes the other channel.

Towards Push-button Solutions: Design Automation for NLoCs

The design of NLoCs is thus far mainly conducted by hand and by “trial-and-error” approaches. Therefore, we aim for providing a design tool support for this promising technology. Details on physical realizations and first directions towards automated design solutions can be found in the following papers:

- Introduction of the NLoC paradigm including physical level design aspects (e.g. channel characterizations): Networked Labs-on-a-Chip (NLoC): Introducing networking technologies in microfluidic systems

- By addressing multiple nodes, complex experiments can be conducted without a re-injection of droplets: Addressing Multiple Nodes in Networked Lab-on-a-Chips without Payload Re-injection

- Simulation of the “macroscopic” evolution (i.e. the speed and trajectory) of droplets in NLoCs by exploiting the microfluidic-electric-duality Modeling, Simulation and Experimentation of Droplet-Based Microfluidic Networks

- An automated method for determining application-specific architectures for Networked Labs-on-Chips: Design of Application-Specific Architectures for Networked Labs-on-Chips

- Methods for validating and dimensioning the specification of microfluidic networks: Automated Dimensioning of Networked Labs-on-Chip

- A discrete model to efficiently determine the droplet’s path and positions (a requirement for advanced design automation solutions) A Discrete Model for Networked Labs-on-Chip: Linking the Physical World to Design Automation

- Verification of NLoC architectures, i.e. verification whether it is possible to correctly route the droplets Verification of Networked Labs-on-Chip Architectures